Key Highlights

- Thermowood is created through a natural, chemical-free process called thermal modification, using only heat and steam.

- This treatment enhances the wood’s durability, making it highly resistant to rot and decay compared to untreated wood.

- The process significantly reduces the wood’s moisture content, leading to excellent dimensional stability.

- As a completely natural and non-toxic material, Thermowood is a top choice for sustainability.

- Its beautiful, rich color provides an aesthetic appeal similar to tropical hardwoods.

- Thermowood offers a long lifespan with minimal maintenance, making it a smart investment for your home.

Introduction

Are you thinking about using a wood material that looks good and lasts a long time? Thermowood could be just what you need for your next job. This material is a type of thermally modified wood that more people want because of what it can do. Through a thermal modification process, regular wood goes through high heat. This changes the wood, making it more durable, stable, and better for the environment. Thermowood is great for people who want the wood to hold up and look nice for many years.

Understanding Thermowood: Definition and History

Thermowood is wood that gets better through a natural process that uses heat and steam. The way this technology started is interesting. People have worked on improving how to keep wood good for a long time. What began as old ways to protect wood has turned into a smart and modern process you see today. Many people now use this high-quality material all over the world. Below, you will find out more about how thermowood started and the big steps that made it what it is now.

What is Thermowood Timber and How Did It Emerge?

So, what is Thermowood timber? It is a kind of thermally modified timber. The wood goes through a heat treatment process. This heat treatment uses high temperatures and steam. It changes the wood’s main parts and properties, but does not use any chemicals.

The idea for Thermowood came from a lot of research. The big breakthrough happened in Finland in the 1990s. The team at VTT Technical Research Centre made the method better. People wanted a durable and eco-friendly choice instead of regular treated wood which uses chemicals. This helps to keep the quality and performance the same every time. It was the start of a new time for sustainable and strong wood products.

Key Milestones in Thermowood’s Development

The journey of Thermowood has several important milestones. Early experiments with heat-treating wood date back to the 1940s in the United States. However, these initial attempts had limited success due to strength loss in the final product.

It wasn’t until the 1990s in Finland that the process of thermal modification was refined into a commercially viable technology. This led to the establishment of the International ThermoWood Association in 2000 to regulate quality and promote the material. This organization standardized the heat treatment process, ensuring that all trademarked products meet high durability and sustainability standards.

| Milestone | Description |

|---|---|

| 1940s | Early experiments in the U.S. to heat-stabilize wood. |

| 1990s | The modern ThermoWood process is developed and perfected in Finland by VTT. |

| 2000 | The International ThermoWood Association is founded to standardize quality. |

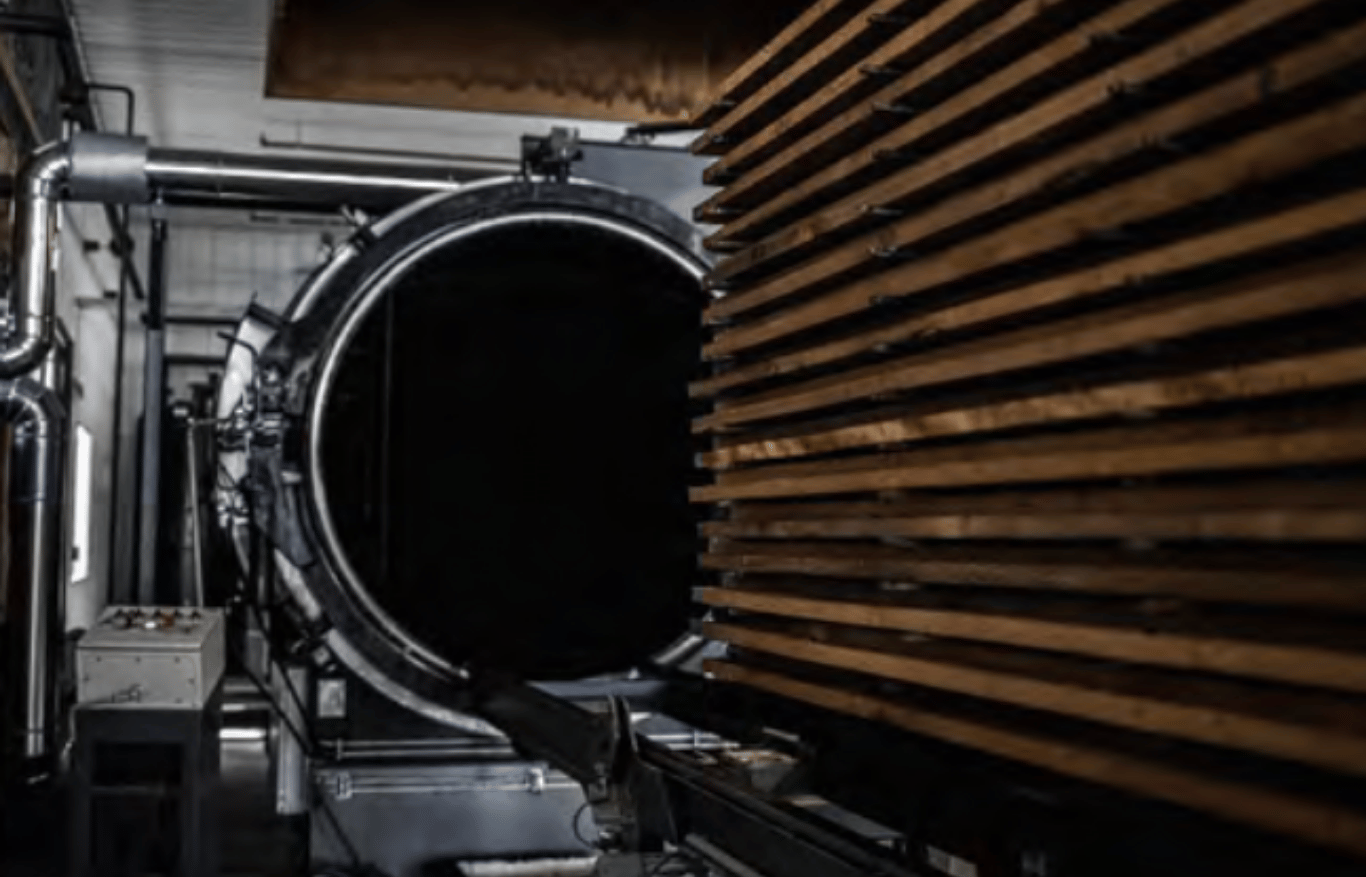

How Thermowood Is Made: The Thermal Modification Process

Thermowood is made using a special heat treatment called thermal modification. In this process, the temperature of the wood goes up slowly inside a space with little oxygen. Steam is often used to stop the wood from burning and helps with the changes inside the wood.

This way, the wood is changed deep inside. It becomes much more durable compared to treated wood that people use most of the time. Here, we talk about the steps that go into this thermal modification process. We also share which types of wood people often pick for thermowood.

Step-by-Step Thermowood Details and Technology

The Thermowood process uses heat to change the wood in stages. It takes up to 5 days. This thermal modification process changes the wood cells, so the wood works better and lasts longer.

The heat treatment process has three main steps:

- High-Temperature Drying: The wood is heated to about 212°F. This step drops most of the moisture content from the wood.

- Intense Heat Treatment: The process then turns up the heat to between 320°F and 450°F and holds it there for hours. Steam keeps the wood safe and helps with the modification. In this step, heat breaks down hemicellulose, which are natural sugars in wood. This stops the wood from soaking up water and also keeps rot and fungi from using the wood as food.

- Cooling and Conditioning: The wood is slowly cooled down. Moisture is brought back in so it stays steady at about 4-6%.

This controlled thermal modification makes heat-treated wood in different classes. You get varying levels of durability and changed color. The final outcome depends on the use of the thermowood.

Common Types of Wood Used for Thermowood Materials

There are many different types of wood you can use to make Thermowood materials. The heat treatment works on both softwood and hardwood. This opens up a lot of options for how you want your home to look and what you want to do with the wood.

Some types of wood that are often used are:

- Softwoods: Pine, including Radiata Pine, and Spruce are used a lot. People like how their grain looks and how these softwoods react to the heat treatment.

- Hardwoods: Ash, Red Oak, Maple, Birch, Alder, Poplar and Aspen are picked many times too. These hardwood choices give you a durable and deep color, so they look good for high-end uses.

The type of wood you pick—whether softwood like Pine or Spruce, or hardwood—affects the color, the grain, and how the Thermowood will perform. This gives you many ways to enjoy the look you want in your home.

Main Benefits of Thermowood for Homeowners

Choosing Thermowood products for your home gives you many good things. One of the main benefits is its strong durability. It has great dimensional stability and good rot resistance. The way Thermowood is made lowers the moisture content in the wood. Because of this, the wood is not likely to warp, swell, or shrink when the weather changes.

Thermowood also stands out when it comes to sustainability. There are no chemicals used in the process, so it is a very green choice for people who care about the environment. In this piece, we will look at these benefits of Thermowood, such as moisture content, dimensional stability, rot resistance, durability, and its focus on sustainability, in more detail.

Enhanced Durability and Resistance Compared to Regular Wood

One of the best things about Thermowood is its long-lasting strength. It lasts much longer than untreated wood. Thermowood does not rot or break down easily. Its heat treatment takes out the parts of wood that bugs and fungi eat, so those things do not touch this material.

The process also gives Thermowood amazing dimensional stability. Regular wood can take in water from the air, and that makes it bigger or smaller at different times. But Thermowood does not soak up much water, with up to 90% less moisture going in. The size of the wood stays nearly the same year after year.

With durability and stability like this, Thermowood is great for outdoor use. Use it for decking, siding, or fencing. It stands up well to weather and lasts for a long time.

Environmental Friendliness of Thermowood Material

If you care about sustainability, Thermowood is a great pick. The wood’s natural properties get better during the process, and there is no use of any chemicals. It only needs heat and steam.

This means it is safe for your family and the environment. Thermowood is a natural choice, unlike treated wood, because treated wood may have chemical preservatives. Thermowood does not use any of these chemicals.

When Thermowood gets to the end of its life, you can recycle it or throw it away like any untreated wood. The focus on sustainability from beginning to end makes Thermowood a good option for building today.

Popular Uses for Thermowood in the United States

Thermowood products are getting more and more popular in the United States. The reason is simple. These products are tough and last a long time. They also do very well in different weather, which makes them perfect for tough outdoor use. Plus, thermowood has a beautiful appearance. It makes any design stand out.

Thermowood products are getting more and more popular in the United States. The reason is simple. These products are tough and last a long time. They also do very well in different weather, which makes them perfect for tough outdoor use. Plus, thermowood has a beautiful appearance. It makes any design stand out.

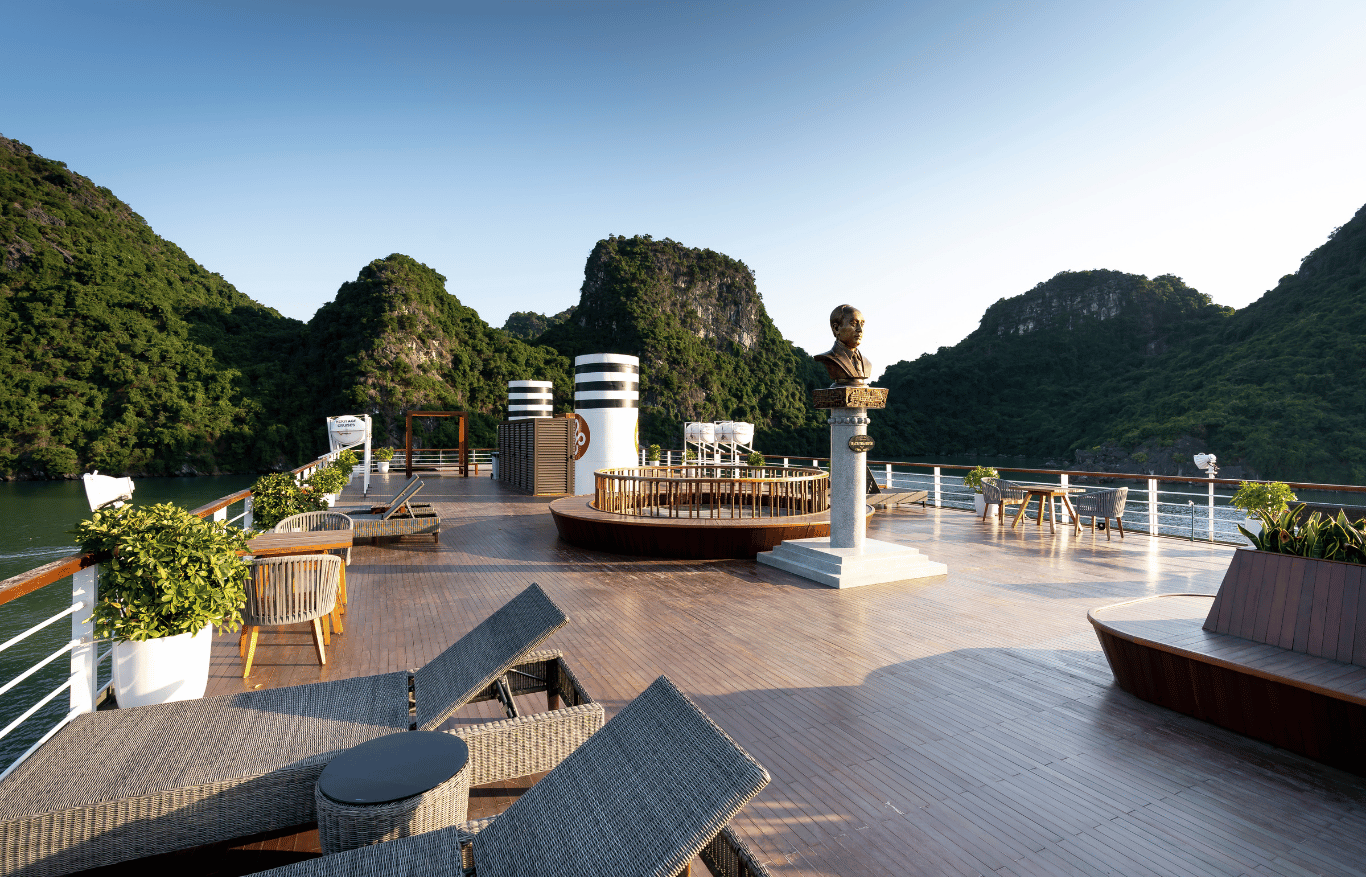

You can use thermowood for many things. People like it for stunning cladding and for decking that lasts for years. It is also a top choice inside saunas. In every way, thermowood shows just how versatile it can be. Its warm, rich look brings elegance to both outdoor and indoor places. The aesthetic appeal can improve any space.

Here, we will see popular ways people use thermowood, and we will also look at some comparisons.

Thermowood Cladding, Decking, and Outdoor Projects

Thermowood is a great choice for outdoor jobs where you need something strong. It resists moisture and decay well. This means you get material that looks good year after year.

Common uses include:

- Cladding: Thermowood cladding gives your home a natural wood look. It helps protect the outside from rain and wind. It will not bend or crack easily.

- Decking: If you want a strong deck that can handle rain, sun, and lots of walking, Thermowood decking works well. It does not need much care.

- Fencing and Landscaping: Thermowood lasts a long time. It is a good pick for fences, garden spaces, and other outdoor projects.

Thermowood products give you the nice look of tropical hardwoods. They come from forests that are managed the right way. So, you get outdoor wood that is good for the earth and it has strong durability for all your needs.

Comparing Thermowood Materials to Other Exterior Solutions

How does Thermowood do when you match it with other choices? If you put it next to normal treated wood, Thermowood comes out on top for dimensional stability. It also does not have any chemicals. This makes it a safer and better option for the world we live in.

You may spend more at first, but over time, it makes up for this. With good long-term performance and less work to keep it looking good, Thermowood gives you a smart and cost-effective choice that will last.

Care, Maintenance, and Longevity of Thermowood Timber

One good thing about thermowood is that it lasts a long time and needs very little care. It does not break down fast, and it stays strong for many years with the least amount of work from you.

To help your thermowood last even longer and stay nice, you should follow some easy steps for care. Here, you will see what simple things you can do to take care of it. You will also find out how it stands up over time.

Maintenance Requirements and Best Practices

Thermowood is loved because it needs very little care. It is very tough against moisture and rot. You do not have to use a lot of chemical treatments on it the way you would with some other woods to let it do well outside.

Here are some best ways to keep your Thermowood in good shape:

- Cleaning: You only have to clean the surfaces with water and a mild soap when you need to. This will help get dirt and other things off the wood.

- Color Preservation: If you do not treat it, Thermowood will slowly turn a nice silvery-gray color with time. If you want to keep the deep colour it starts with, you can use a UV-protective finish or pigmented wood oil now and then.

This easy way to care for it will help your Thermowood look good and last for years without a lot of work.

Expected Lifespan and Performance Over Time

You can get a very long life from Thermowood timber. The thermal modification process boosts its durability, making it as strong as some of the toughest types of wood in the world. The process helps common softwoods move up from a low to a high durability class, like moving from Class 1 to Class 3.

Because of this level of durability, your siding, deck, or fence made from Thermowood will fight off decay and stay strong for 30 years or more. Even in tough weather, it will hold up well. There will be very little warping, splitting, or swelling as time goes on.

When it reaches the end of its life, you can get rid of Thermowood in a safe and clean way. It has no harmful chemicals in it. That makes it a good choice for you and for the earth, all the way from start to the end of its life.

Choosing the Best Thermowood Suppliers in the USA

Not all thermowood is the same. The quality you get comes from how the thermowood is made. The process matters a lot. You need to pick from good thermowood suppliers. This is the only way to make sure you get all the benefits you want from these thermowood products.

If you live in the USA, it is important to find a supplier who cares about quality and cares about sustainability. Eco Hearth is one of those suppliers. We offer top thermowood products you can trust for your home. Now, let us see what makes a supplier stand out. There are good reasons why Eco Hearth is a top pick for people who want thermowood and think about sustainability.

What to Look for in a Quality Thermowood Supplier

When you choose Thermowood suppliers, you should watch for some signs that show you are getting good quality. The way to change wood the right way is not easy, and new makers often have problems, like the wood getting too hard or the color turning out wrong.

You want a supplier that shows:

- Commitment to Quality Control: A good supplier follows strict rules from groups like the International ThermoWood Association. This makes sure the wood is treated well and has high durability.

- Focus on Sustainability: The best companies get their wood from forests that are managed with care for the earth. They are open about what they do for the environment.

It is also good if the company offers many kinds of products and has people who know what they are doing. This tells you they can help you get the best Thermowood for your work.

Where to buy Thermowood in United States? Eco Hearth Is the Leading Choice

When you want to be sure you get the best, Eco Hearth’s Thermowood is a top pick. We work hard to bring you the highest quality thermowood products out there, so your project goes well from start to finish.

At Eco Hearth, we focus on both durability and sustainability every step of the way. We get our thermowood from forests that are managed in the right way. We use new technology to treat the wood. You get treated wood that stays strong over time, looks nice, and has a steady finish.

If you pick Eco Hearth, you do not have to worry about poorly treated wood. Instead, you get a product that does what it promises. You can trust us to give you strong, long-lasting, and eco-friendly thermowood for your home.

Conclusion

To sum up, Thermowood gives you a strong and long-lasting choice if you want to improve your living space. The thermal modification process used with this material makes it tougher against the weather. It also fits well with eco-friendly ideas. If you are thinking about cladding, decking, or other outside work, Thermowood is a smart and stylish pick.

When you look at your choices, remember to go with a good supplier. This helps you get quality. Eco Hearth is a top name in the Thermowood market and brings both durability and good looks to its products. If you want to see how Thermowood and the thermal modification process can help your home, contact us today!

Frequently Asked Questions

Is Thermowood More Durable Than Untreated Wood?

Yes, Thermowood lasts longer than untreated wood. The thermal modification process makes the wood tough against rot, decay, and bugs. It does this by taking out the wood’s natural food for these problems. So, Thermowood stays good for a long time, even outside.

Does Thermowood Require Special Maintenance or Treatment?

Thermowood needs very little care. You do not have to use chemicals on it to keep away moisture or to stop rot. Just clean it now and then. If you want the dark color to stay, you can use a UV-protectant oil, but you do not have to.

How Much Does Thermowood Typically Cost Compared to Other Modified Woods?

The cost of thermowood can change, but it is seen as a top building material. The price shows its good durability, stability, and sustainability. Over time, thermowood gives great value since you do not need to replace or fix it often.